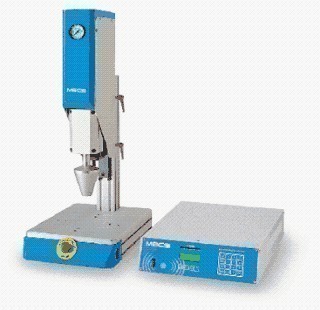

Ultrasonic Welder

An ultrasonic welder is a device that uses ultrasonic sound waves to weld metals and plastics. Although most people are unaware, ultrasonic welders are often used to produce, seal, and package many everyday items such as milk jugs, butane lighters, and soda cans. Many different industries, such as the aerospace, automotive, medical, computer, and electrical industries use ultrasonic welders for a wide variety of applications such as cutting, sealing, joining, packaging, or bending. Ultrasonic welding is most often used when an object is too small or delicate to undergo more common welding methods.

How does an Ultrasonic Welder Work?

One or more objects are placed in a clamp that is usually specifically designed to mold the objects in a certain way. Pressure is applied to the objects while a simultaneous burst of 50 kHz ultrasonic frequency is directed at either the entire object or concentrated on one area. The ultrasonic frequency causes the objects’ surface molecules to vibrate so fast that they collide into one another and fuse the object together. This process usually takes less than one second.

Advantages and Disadvantages

Ultrasonic welders are extremely fast, easy to use, and can be used in situations that other welding methods cannot. For example, when a company produces flammable, explosive, or delicate items such as ammunition, butane lighters, and electronic microchips, heat cannot be used. Ultrasonic welders do not produce heat and cannot harm the object. They do have their disadvantages, however, as they cannot penetrate thick materials like metal. Because of this, most metals must be welded via traditional welding techniques. Of course, ultrasonic welders can weld metals such as aluminum because they are thin enough to vibrate under the ultrasonic frequency.

Health

As with any industrial machine, precaution should be taken when handling or working around an ultrasonic welder. Users should never place a body part in front of the machine when it is activated and objects that are not being welded should always be removed before the machine is turned on. While humans cannot hear ultrasonic frequencies, ultrasonic welders may produce extremely high-pitched sounds that can damage the human ear. Because of this, ear protection should be worn while working around an ultrasonic welder at all times.

Where to Find an Ultrasonic Welder

The most popular manufacturer and distributor of ultrasonic welders is the company that invented them, Sonobond Ultrasonic, which has been producing ultrasonic welders since 1960. Other companies that manufacture and sell them also exist: Sonitek, Balkowitsch Enterprises, Branson Ultrasonics, and Dukane. Sonics, HeatStaking, and Herrmann Ultrasonics are also good places to look. Generally, any company that produces industrial equipment either sells ultrasonic welders or the company’s owner(s) knows where to find one.

Comments - One Response to “Ultrasonic Welder”

Sorry but comments are closed at this time.