Auger Electron Spectroscopy

Pierre Auger discovered the Auger effect with x-rays that were involved in simultaneous cloud chamber usage. Auger observed that excited atoms emitted energetic electrons when the atoms relaxed. When the Auger effect was first discovered, it served little to the scientific community and was not utilized until the 1950s. The effect was then used to help improve the experimentation of chemical/compositional surface environments, in metallurgy, and in microelectronics.

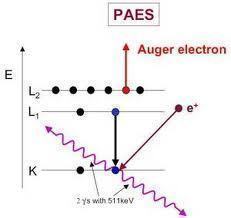

How Auger Electron Spectroscopy Works

Auger Electron Spectroscopy is when specialized equipment that can test samples of materials is used to measure the kinetic energies that result from “Auger electrons” that escaped from the surface. This application is called Auger Electron Microscopy. The process must take place in a vacuum for accuracy and to prevent contaminants from entering the testing area. The equipment can then use these measurements to render imagery of the sample’s surface.

Almost any solid can be a test sample for analysis. Sample size depends on the size of the auger electron spectroscopy equipment. The only preparation necessary is slightly cleaning some samples. A dirty sample can cause the machine to become clogged or cause other general cleanliness issues.

The Length of Analysis with Auger Electron Spectroscopy

The estimated time for testing samples depends on the image’s quality. A simple survey spectrum takes around 1-5 minutes depending on the sample. High resolution imaging usually takes between 5-25 minutes in each region of the sample. Each region that is analyzed is rendered based on the resolution of the image that is necessary.

Images can be magnified to up to 20,000 times its size by scanning with the equipment. The sweep scan of electrons flowing over the surface is a lengthy process. This is done per section through raster scanning. It can take several hours to complete each surface’s composition maps depending on the size of the sample being analyzed.

Applications of the Auger Electron Spectroscopy

Elemental Surfaces Analysis – Surfaces of solids can be identified and quantified via Auger Electron Spectroscopy equipment. Elements between Lithium and Uranium can be observed within a sensitivity of 0.5 atomic percent. This means that any surface can be tested and the elemental composition can then be determined based on what is viewed through the equipment.

Depth Profiling – The equipment can also be modified to provide an in depth analysis of thin film materials. The removal of layers in succession via Argon ions can provide an elemental analysis through depth. This process is useful for volumetric and bulk analysis of materials. An alternative use of this process makes it possible to find impurities and any diffusion of the material at junctions or grain boundaries.

Small Feature Analysis – The power of the imaging makes it possible to measure and investigate features on the surfaces of materials approximately 25 nanometers in size. The average strand of human hair is between 50,000 to 70,000 nanometers thick and would be extremely large if viewed through Auger Electron Spectroscopy equipment.

Phenomena Analysis – Any phenomena that materials undergo (such as the absorption, desorption, or surface segregation) can be viewed through the use of Auger Electron Spectroscopy. Deep analysis can be done to gain scientific data about specific manufactured materials designed to increase or reduce the phenomena.

Reactivity Analysis – Chemical reactivity occurs on the surface or in any localized area of materials. This can be done with a wide range of chemicals, materials, and anything that Auger Electron Spectroscopy equipment can test.

Atomic Concentration Analysis – The material’s atom concentration can be measured in whole or in part. With the use of the equipment, any material can be tested to understand the concentration of specific elements or all elements that compose the sample.

Materials Deposit Analysis – The material deposit on the surface of the sample can be observed. This can be done with nearly any material that would be worth testing or with materials that are being developed for specific purposes.

Limitations of Auger Electron Analysis

Since a focused electron beam is used to analyze materials placed in a vacuum with the Auger Electron Spectroscopy equipment, there are a wide range of limitations. The main concern is the process of analyzing specific samples.

Samples that have the properties of conducting and semiconducting elements can be easily processed. Specialized procedures and a highly controlled environment are necessary for any type of non-conducting sample. This also means that multiple sample analysis procedures of the same sample may be necessary before data can be quantified.

Another limitation of the technology is the fact that only specimens that are solid can be analyzed. Liquids and gases are very different within a vacuum chamber. They can either escape or deform, thereby rendering the process ineffective.

Some samples decompose when an electron beam is used on them. This is because irradiation causes the sample to change too much during the scanning process. Therefore, studying these types of samples through Auger Electron Spectrograph equipment is not possible.

The quantification process is complex and requires a great deal of work. The process is so difficult that computerized equipment, which still takes very long to process, must be used in addition to manpower.

Accuracy of Auger Electron Spectroscopy

The Auger Electron Spectroscopy analysis is very accurate. The spatial resolution that is used with most commercial equipment/instruments is within 0.2 or less Mu (micro/millionth) meters.

Accuracy of sampling depth can be about three monolayers (closely packed layer of atoms). This makes it possible to test a very thin film of material if necessary.

Sensitivity and detection can be as little as 0.3% for most materials. This means that sensitivity can detect 0.3% minimum with materials that are suitable or properly prepared for analysis.

Complementary or Related Techniques of Auger Electron Spectroscopy

The technology that is used in Auger Electron Spectroscopy can be complimented by a variety of other techniques that use similar processes to analyze materials. Such options include:

X-ray Photoelectron Spectroscopy – A process that measures the elemental composition, empirical formula, chemical state, and electronic state of the material.

Atom Probe Field Ion Microscopy – It is possible to identify individual atoms on a material’s surface with a fluorescent screen. This allows the observation and analysis of atomic processes like evaporation to be possible.

Rutherford Backscattering Spectroscopy – By using high energy ions that are scattered on a surface, the sample can be analyzed to see whether its structure and composition are compatible with other materials.

Secondary ion mass spectrometry – This process is designed to analyze the secondary ions that are a result of bombarding a sample with an ionic beam. The secondary ions can then be quantified in measurements of parts per billion ranges.

Comments - No Responses to “Auger Electron Spectroscopy”

Sorry but comments are closed at this time.